LogiMAT 2025 impressions

Mar 26, 2025Introduction

Two weeks ago our team visited for the second year in a row the LogiMAT show in Stuttgart. For those who have not had the chance to visit, we cannot recommend it highly enough. It is an excellent exhibition for all things logistics which takes place annually (not only in Stuttgart but around the world). This year, the conference was attended by approximately 65,000 people from March 11 to March 13. Shocking that this many people were even able to attend given the public transit strikes that occurred across Germany on Monday that week (we were almost certain our flights were going to be cancelled).

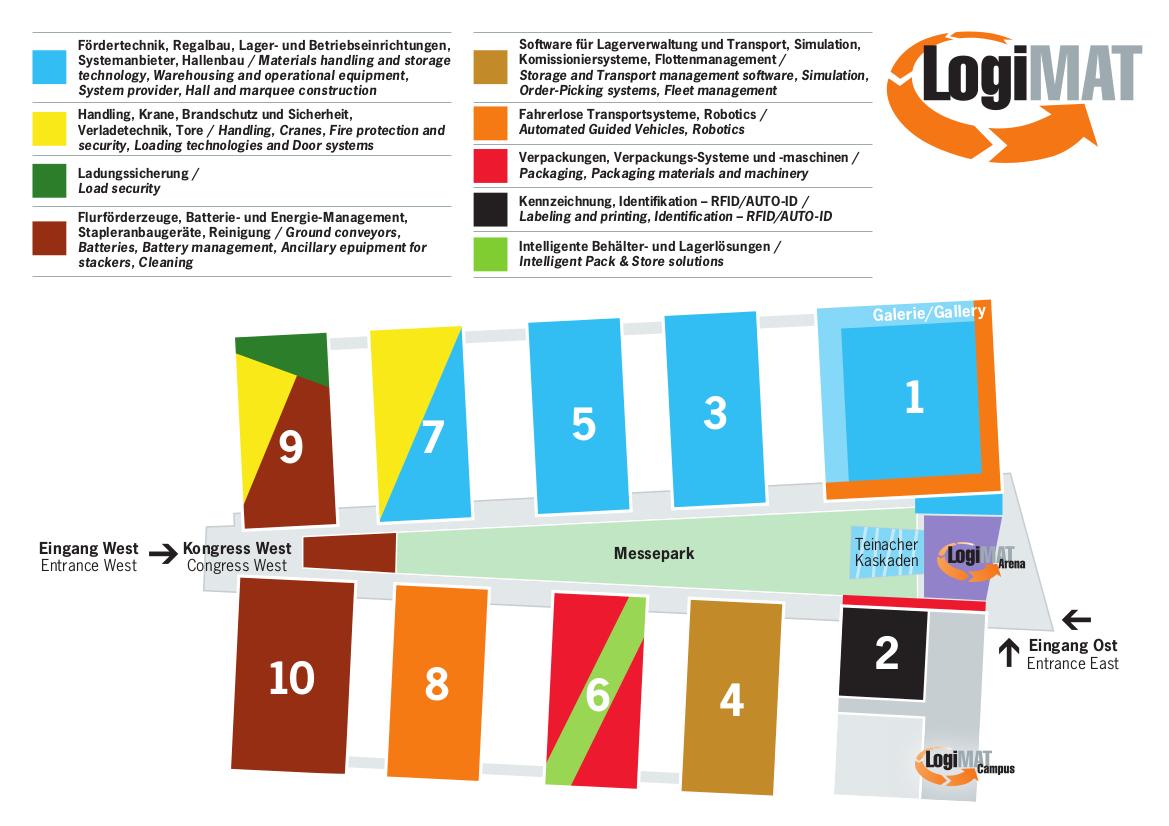

To give some scope to the size of the event, the entire Stuttgart Messe is utilized, and the halls are broken up into the following logistics focuses:

- Halls 1, 3, 5 and 7: Material handling and storage technology, Warehousing and operational equipment, System provider, Hall and marquee construction.

- Halls 7 and 9: Handling, Cranes, Fire protection and security, Loading technologies and Door systems.

- Hall 9: Load security.

- Halls 9 and 10: Ground conveyors, Batteries, Battery management, Ancillary equipment for stackers, Cleaning.

- Hall 4: Storage and Transportation management software, Simulation, Order-Picking systems, Fleet management.

- Hall 8: Automated Guided Vehicles, Robotics.

- Hall 6: Packing, Packaging materials and machinery.

- Hall 2: Labeling and printing, Identification – RFID/AUTO-ID.

- Hall 6: Intelligent Pack & Store solutions.

We attended last year with just two of us and this year we attended with five: this felt more appropriate for what we wanted to see. We didn’t see nearly enough of the show last year in the two days we attended. So this year we came with five of our team members with a plan to split up across the halls. Over both days we were there we managed to cover almost everything we wanted to see, but creating some sort of a plan is KEY. This is a huge show and for people who are interested in this kind of stuff, you can quickly get lost. We spent half of the first day walking around Hall 1 before realizing what time it was and we had only walked through half of the hall as we really wanted to stop and talk to everyone.

Highlights from the show

If you haven’t been before, the thing you will be most impressed with is the effort that goes into setting up some of these booths and the automated solutions vendors bring. Autostore (and many of their partners) regularly bring actual working grids with multiple bots performing picking tasks throughout the day. SSI Schaeffer and others brought vertical storage lifts and had them fully operational. HAI and Geek+ had some of the coolest booths with the sheer amount of automation they had in working. But, there are a few things we want to highlight that we noticed this show:

Focus on AI

Yes, we know, but it has to be mentioned. And the difference from last to this year is noticeable: anyone who can toss “AI” or “AI-powered” on a logo or on their branding certainly took the opportunity to do so. And we’ll be honest: we didn’t spend a lot of time talking to people about what the AI solutions were bringing. Sometimes its easy to get lost in the argument of what is actual AI in these practical applications: just some advanced algorithms or is it something more. In any event, it’s on the forefront of CIO’s minds. According to a 2024 study by Infosys, “40% of logistics and supply chain companies reported CIOs as the main sponsor of generative AI initiatives.”

Expanding grid storage solution market

In recent years we have seen a huge uptick in grid-based storage solutions implemented in the D365 WMS space. Autostore is the clear industry leader, and last year we commented on the number of high-density storage solutions, but these grid-based solutions are growing rapidly. This year we saw the introduction of a fully-integrated pick & place robotic arm at an Autostore port (more on that later) and a cold-storage Autostore instance (from Swisslog – very cool…pun fully intended), but we also noticed some interesting other providers such as Gridstore. Gridstore has a unique take on the problem: whereas several providers require in a single column the same tote size, Gridstore can handle three different sizes of totes. This provides much more flexibility to what you need to store (and they can handle up to 50kg per tote, too).

Sustainable warehousing

Depending where you are in Europe, you will see varying levels of sustainability initiatives with warehousing. But at this show there was a clear direction from several organizations to showcase their products in a sustainable manner, or in several cases the whole company’s focus was sustainability. Take for example Faubel’s Logistics Labels. These e-paper displays with integrated RFID tags provided a paperless way to track all your closed-loop containers/pallets. And, they are totally battery-free. No charging, no paper.

Looking at sustainability from another angle, this year we noticed a ton of exoskeletons for warehouse workers. Several companies are focused on designing and delivering exoskeletons which promote proper posture throughout logistics activities, which can of course reduce sick leave and keep people happy and healthy. Others are taking it a step further and actually providing exoskeletons which increase your strength in certain activities, allowing workers to lift more (or just lift with less effort).

Our team's favorite products

We saw a lot. More than we can possibly post about. But we took the time to ask each team member who attended a few questions:

What was your favorite product from the show?

What was so interesting about it?

How do you see this bringing value to your customers?

Could this be used in a D365 WMS implementation?

Will Pyburn

For me, the CarouselPort 4.0 AI from Autostore was incredibly cool. This is an integrated pick & place bot which is an actual Autostore product, developed in partnership with Berkshire Grey, which has object recognition technology separate from the arm to identify the product it needs to pick from the Autostore port/bin.

What I thought was particularly cool about this pick & place bot was how fast it was in identifying what it needed to pick and how precisely it was able to identify the goods in (up to) 4-split bins.

Obviously, anyone who is deploying a new Autostore grid, if their product line makes sense I would suggest they use this. It really looked like a very seamless picking operation, and the fact that it's natively integrated into Autostore's task interface is a HUGE plus. Autostore didn't provide numbers at the booth regarding pick speed but I'm sure when this is released (around mid-July?) that information will become apparent.

So clearly the prerequisite is you need to have an Autostore grid in your implementation. But the beauty of this solution is there's no additional interfacing to the pick & place bot. So if you are integrating from D365 WMS directly to the task interface from Autostore, it just works. That's all handled by the Autostore controller. The same would go for any of Autostore's partners who deliver software which works with the task interface. The fact that you don't need to do anything additional is a huge benefit. Of course this means it's not as versatile as using another pick & place bot, as you couldn't have it perform other actions, but for picking from Carousel ports this seems to be a pretty solid solution.

Pien van der Tas

My favorite product was Modula FlexiBox (Modula Flexibox | High-Speed Automated Storage Bin System). This is a combined Vertical Storage Tower and Automated picking solution. Like the "normal" VST, it presents the user with a tray, but on each tray, totes are placed from which items need to be picked. Thus, only totes that are required for picking will be presented to the user.

This will make it easier for the user to pick multiple orders or items from different totes at ones, without waiting for another tray. Furthermore, the Flexibox will prepare the next tray during the picking. I think this will bring values for customers that do not have a lot of space in the warehouse and also for customers that have a lot of "smaller" items to deal with. It is ideal for those who want to optimize the picking process instead of presenting a full tray with items that do not need to be picked. Furthermore, we heard (but cannot find information from it online) that it can be replenished from the back side of the machine, which makes the machine usable for inbound without pausing the outbound operations.

This can be used in a D365 implementation in combination with, for example, cluster picking when many orders need to be picked in smaller quantities.

Demi van der Weijst

The ForwardX Lynx O1500 is an impressive autonomous mobile robot (AMR) designed by ForwardX Robotics. It's built to transport heavy loads of up to 1500 kg, making it ideal for handling a wide array of automotive components and other heavy items. ForwardX Robotics showcased two types of AMRs, where the Lynx O1500 is there newest product.

What sets this AMR apart is that it comes with a pair, which allows it to maneuver through crowded warehousing floors. Moreover, the Lynx O1500 has the ability to move omnidirectionally and handle diverse payloads of varying dimensions.

I can see this product working in various industries. Especially where they store many pallets with heavy items. In a D365 WMS implementation, the Lynx O1500 could be integrated to enhance warehouse management processes, say repeated staging of pallets from outfeed conveyor lanes or movement of pallets from inbound staging to putaway areas.

Max Meyssonnier

The Skyrail is an overhead conveyor system that helps move goods within warehouses and factories. Instead of using floor space like traditional conveyor belts or forklifts, it moves items through a rail system above that can also go up or down. (I am not sure if you can also like store items or if this is just to move items).

What I find interesting is its smart use of space. Most heavy items are usually moved on the ground, which takes up a lot of room, requires special safety measures, equipment, and/or people, and can generate bottlenecks.

This Skyrail literally moves goods overhead, freeing up space below and making moving heavy items in warehouses safer and more efficient without bottlenecks. It can scale up or down by adding more “robots”. The other interesting point is the very high transport speed up to 150 m/min, depending on the total weight

This could be highly valuable for auto parts customers but also any customer with heavy products. It would help move heavy items within mezzanine areas or when large products need to be stored separately, such as near loading docks. With this solution, these items could be stored anywhere in the warehouse, as transporting them would no longer be a challenge.

It could easily be integrated with a WCS. Since conveyors simply move items, the setup would be straightforward. In D365 WMS, it would just translate into a pick-and-put pairs.

Jan Jusup

For me, the Geek+ robotics solutions was the favorite.

Geek+ warehouse robotics showcased an end-to-end robotized warehouse concept at the fair. They presented their PopPick shelf-to-person solution, the RoboShuttle tote-to-person solution, and SkyCube pallet-to-person solution. They showed that a warehouse can be fully automatized, with just replenishing and picking being done by humans at the designated gates.

The solutions are not necessarily novelties in the area, but seeing three different solutions work seamlessly at their impressive stand was very memorable. The SkyCube solution showcased was very tall, showcasing just how much space can be used for the complete solution, all while the small robots were swimming underneath to deliver the picked totes to the correct location. Their real-time tracking also looked very cool.

I can see their products working in a fully or semi-automated warehouse. I can imagine them speeding up order fulfilment and increase the number of orders processed. The SkyCube maximizes the storage space to the fullest, making it easier to organize totes. This can be combined with their pallet storage system as well, so different packaging can be handled as well. Anyone striving to eventually achieve a fully automated warehouse should look at this.

MHEI would have to be used to integrate with this system, but seeing their WES in action, it feels like this could be straightforward for D365. Work headers would have to be sent to them, but a white-box solution would be great here. I can see additional modules of their system being installed and integrated over time with ease. The modular approach seems to be the desired solution these days, as it enabled to invest capital gradually.

Conclusion

While our main focus is D365 WMS implementations, InterRadish is also a reseller of several mobile device technologies. We want to provide as much value as we can to our customers who are implementing D365’s WMS and to do that, not only do we need to know about mobile devices and the various providers, but about anything in the warehouse which could improve our customer’s operations. Our focus is not only on the software side but is really, primarily on the logistics side. Good processes supported by purposeful hardware will make any system implementation easier. This is why shows like LogiMAT are so important to us: we have to stay up to date on what the market is doing and what solutions are coming out.

Now, the most important thing from this show is the apparent lack of Microsoft solutions and/or branding. Yes, it’s primarily a hardware show, but there is a hall for software solutions. Throughout the halls, literally every single hall, you see SAP branding everywhere. So many of the solutions that were presented were presented as SAP-enabled or easy integrations to SAP. Several of the vendors there were SAP implementation firms or had SAP EWM consulting teams present. There was a distinct lack of Microsoft partners or Microsoft-enabled solutions. This is what we will continue to try to change year after year: bringing more D365 WMS knowledge to the market. Whether that means a (co- ?) sponsored booth with Microsoft, or our own booth in the future, or bringing our products and services to the market in Germany, we will continue to work towards this goal. We will be back in Stuttgart in 2026, and we hope to see many of you there!